THE ADVANTAGES OF INVERTER WELDING CONTROLS ON SINGLE PHASE DRUM WELDING MACHINES

单相钢桶缝焊机采用逆变焊接控制装置的优点

作者: 威廉姆斯先生, 英国联邦焊机国际有限公司总裁

1-TYPICAL SINGLE PHASE AC DRUM WELDING

典型的单相交流钢桶焊接

The actual amount of energy required to make the seam weld is about 60 kilowatts so why does a typical drum welding machine require an electrical supply of 250kVA ?

产生缝焊所需的实际能量是60千瓦左右, 为何典型的交流桶焊机需要250千伏安的电源?

The reason is that Drum welding machines require a large amount of ‘reactive power’ in addition to the ‘true power’ required to make the weld.

其理由是桶焊机除了需要产生缝焊的实际功率之外,还需要大量的无效功率。

This reactive power generates the magnetic fields which are essential for inductive electrical equipment such as the welding transformer and electric motors to operate.

Reactive power is measured in units of kVAr (kilo Volt Amperes reactive), whilst ‘true power’ is measured in kW (kilowatts).

此无效功率产生的磁场对诸如运行的焊接变压器和电机的感应电器设备来说是重要的。该功率测量单位为kVAr(无效的千伏安),而实际功率测量单位为kW(千瓦)

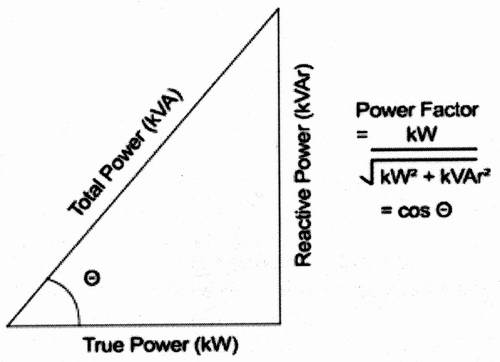

Fig1 图1

图1中 Total Power为总功率,TruePower为实际功率,Reactive Power为无效功率,Power Factor为功率系数

We can see in Fig1 the relationship between the true power (used to make the weld) and the reactive power (required by the drum welder) and power factor.

从图1中我们看到实际功率(用于产生缝焊)和无效功率(钢桶焊机所需要的)以及功率系数之间的关系。?

Power factor can be considered a measure of efficiency. In general terms the lower the power factor, the greater the amount of reactive power required.

The highest power factor is unity,1.0….? A typical drum welder can operate at a power factor as low as 0.2

功率因数可认为用于测定功率,总的来说,功率因数越小,所需无效功率 越大。

最大功率因数? 是整数,1.0….。一典型的桶焊机操作的功率因数可达到0.2这样低。

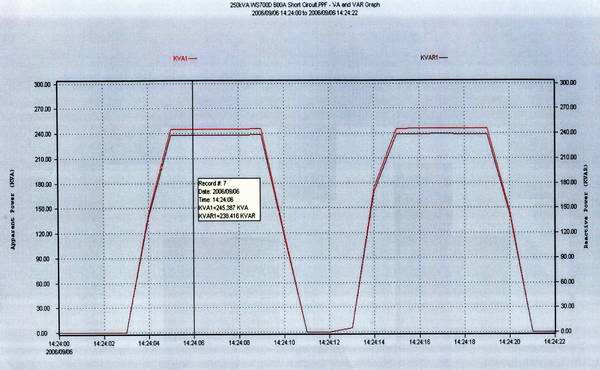

Fig2 图2

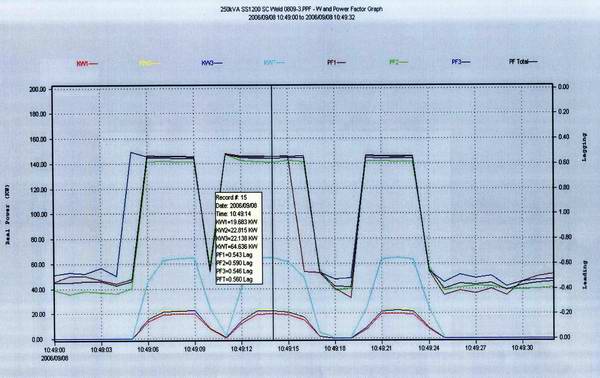

Fig2 shows the actual electrical power measurements taken of a standard two phase AC drum welding machine…The total power is 245kVA and the reactive power is 238kVA

图2 为标准的单相交流桶焊机上实测图, 总功率是245千伏安,无效功率是238千伏安

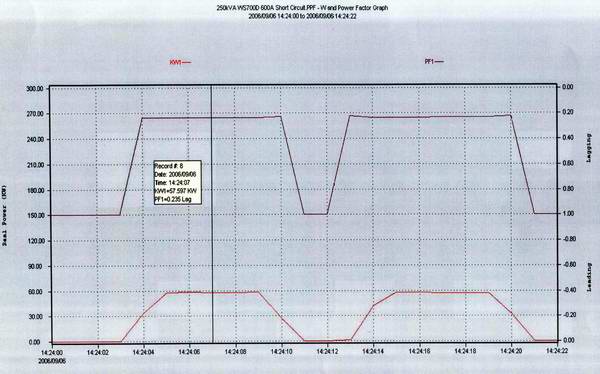

Fig3 图3

Fig3 shows measurements from the same machine, the power factor is 0.235 and the true power reading is 58 kilowatts

图3 为同一设备上实测图,功率因数是0.235,实际功率为58千瓦

Reactive power provides many drawbacks:-

无效功率的许多缺点:

Reactive power supplies no useful work. Furthermore, an excessive 'reactive power/true power' ratio has several negative consequences:

无效功率提供无用功,此外过大的无效功率/实际功率之比有几个付面的结果:

Increased total demand for current

对电流的总需求增加

Additional non-useful load for the lines and transformers

线路和变压器额外增加了无用负载

Need to reinforce the electric facility (non-productive investment)

需要强化电力设施(非生产投资)

Operating situation which comes close to the triggering thresholds of the safety devices

Increase in thermal losses

接近安全装置安全极限的运行情形造成热损失增加。

Decrease in supply voltage

供电电压减少

Also, electricity is generated and supplied to your factories over three phase however the average drum welder is connected to only two of the three phases which unbalances the electrical supply which adds to the inefficiency.

产生了电力并以三相电源提供给需要的工厂,然后,每个桶焊机只和三相中二相连接,这对供电造成不平衡,从而增加无用功。

2-ADVANTAGES WHEN USING INVERTER WELDING CONTROLS

用逆变焊接控制装置的优点

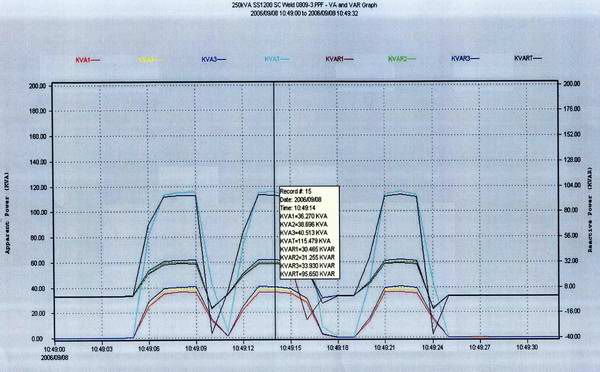

Fig4 图4

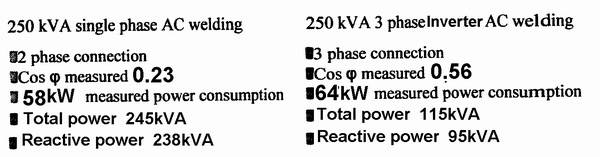

Fig4 shows the measured power of a similar 2 phase drum welder when connected to an SS1200 inverter control. The total power requirement is reduced to 115kVA and the reactive power is reduced to 95kVAr

图4显示同样的单相桶焊机连接到一SS1200逆变控制装置时的实测功率。总功率要求降至115千伏安,无效功率降至95千伏安。

Fig5 图5

Fig5 shows the reduction in power requirement and the power factor improvement of over 50% to 0.56

图5 说明功率要求降低以及功率系数从超过50% 改进到0.56

The true power that is used to make the weld remains the same at circa 60kW

产生缝焊的实际功率仍保持在60?左右。

The advantages of using an Inverter welding control

使用逆变焊接控制装置的优点:

-Balanced power connection across 3 phases

-通过3相供电连接得到平衡

-Greater? power efficiency

-较大功效率

-Superior weld quality with use of full sine wave

-使用全正弦波,焊接优质

-Superior edge weld with precision initiation

-以精确的激发形成优质焊缝边缘

-Constant current

-稳定的电流

-Smaller heat band? due to higher welding frequency

-鉴于较高的焊接频率,热影响区较小

-Improved weld wheel life

-焊轮寿命提高

-Simplified weld control settings

-焊接控制调整得到简化

-Can be connected to standard AC transformer

-可连接到标准的交流变压器

250 千伏安单相交流焊接 |

250 千伏安3相逆变器交流焊接 |

双相连接 |

3相连接 |

余弦:实测值0.23 |

余弦:实测值0.56 |

实测功率损耗: 58千瓦 |

实测功率损耗: 64千瓦 |

总功率:245千伏安 |

总功率:115千伏安 |

无用功率: :238千伏安 |

无用功率: :95千伏安 |

NOTE- Although these readings are from two similar BF drum welding machines we would not expect the results to be too dissimilar when taken on the same machine.

注意:虽然这些读数来自二台类似的BF桶焊机, 但我们并不认为用在同一设备上这些结果会有太大的不同。